Paper is an essential product in daily life. Not only is it renewable, clean, but incredibly versatile: it regularly provides new possibilities, applications, and end-uses. The first use that comes to mind when thinking about paper is writing material but for how long has paper been a core pillar of the packaging industry?

Paper history, a journey through time!

In Europe, papermakers rediscovered tree fibres for papermaking in the 19th century. Several machines and processes were developed in Europe and America for grinding or chemically breaking down wood to produce paper. As wood was abundant and accessible, its use instead of rags made paper production much cheaper. That was the beginning of the mass-produced paper industry.

Paper became the number one packaging choice for many items around the globe for many centuries in the 19th century. Mass production arising from the Industrial Revolution brought some of the most significant changes in packaging. As efficient packaging methods were needed to keep up with yield, storage, and transportation bins, bags, food packaging methods, primary packaging materials, and in-store packaging options were introduced. At the same time, consumers’ behaviours and desires changed: they wanted attractive, individual packaging that was easy to use.

From paper production to fibre-based packaging

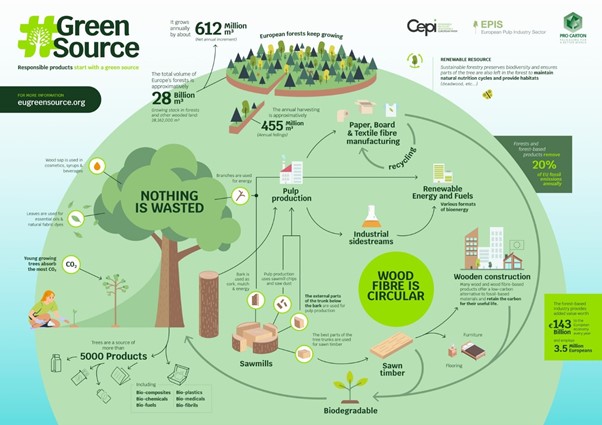

When it comes to packaging, paper has always been an essential material. The paper packaging production process has evolved significantly, and this evolution has sped up in the past two decades. Almost all of today’s paper, and thus paper packaging, is made from wood pulp, using the following process:

Pulping Creating paper starts with the arrival of residues from forest and industry and trees from sustainably managed forests for pulping in the paper mill. From these, fibres are extracted mechanically or chemically and then separated from the lignin. Afterwards, the wood pulp is washed, bleached, and beat to soften. At this stage of the production process, starches, colours, and other chemicals are added, a different mix for each type of paper.

Finally, pulp and chemicals are mixed with water. The resulting paste is moved into large papermaking machines to drain off water and then through a series of heated cylinders to press, dry, and smoothen the paste, ensuring uniform thickness.

When making pulp from recycled fibres, the same pulping process is complemented with several others:

De-inking For certain papers (e.g. printing and writing paper and hygienic products) ink has to be removed from the paper before recycling. Deinking (also de-inking) is any process, in addition to slushing and incidental washing, intended to remove most of the ink particles from pulp made from recovered printed paper or board.

Filtering Paper for recycling is “slushed” into pulp, and large non-fibrous contaminants are removed (for example, staples, plastic, glass etc.). Fibres are progressively cleaned, and the resulting pulp is filtered and screened a number of times to make it suitable to make paper, which can be transformed into packaging.

To transition from paper into packaging, the paper must be converted. The converting processes includes all steps in the transformation from paper to a finished product. These processes consist of printing, die-cutting, folding and gluing (taping or stitching).

Fibre-based packaging: an innovative solution for the pressing issues of our times

Packaging has always been a key enabler of economic growth: by protecting goods, it ensures a longer shelf life and maintains their integrity until delivered to the consumer. Fibre-based packaging is derived from natural, renewable materials and is made of virgin and recycled fibres1 that can be re-used multiple times. Fibres can be reused more than 25 times with little loss of integrity, according to a recent study conducted by the University of Graz2. It is important to note that both virgin and reused fibres are equally important in setting up a more circular economy. Virgin fibres are primarily used for packaging that comes into direct contact with food, while recycled fibres are used for secondary packaging.

Today’s consumers and policymakers are demanding packaging solutions that help us in the fight to build a climate-neutral society. 4evergreen is a cross-industry alliance with the goal of perfecting fibre-based packaging circularity and climate performance. Many of the 4evergreen members have a long tradition of developing low-carbon packaging and we expect that even more packaging will soon enter the market. It is vital that companies bringing new packaging types to the market are aware of the impacts of each material that they use, how it can be recycled and the complexities of collecting and sorting the packaging. 4evergreen members have forged a path for all companies to design, produce, collect, and recycle in a more efficient manner. Together we work to increase the recycling of fibre-based packaging as part of our commitment towards a better future.

A year of collaboration and growth: discover 4evergreen’s 2023 Annual Report!

We are excited to launch 4evergreen’s 2023 Annual Report, looking back at our growth and achievements from the past year and recognising…

4evergreen launches new Ambassadorship programme

4evergreen is hitting the conference floors! This year, the alliance has launched a new Ambassadorship programme that will take us to major…

4evergreen wins European Paper Recycling Award

Brussels, 20 February 2024: The 4evergreen alliance has won a prestigious award from the European Paper Recycling Council (EPRC) in the…